MAINTENANCE OPTIMIZATION USING ADVANCED ANALYTICS

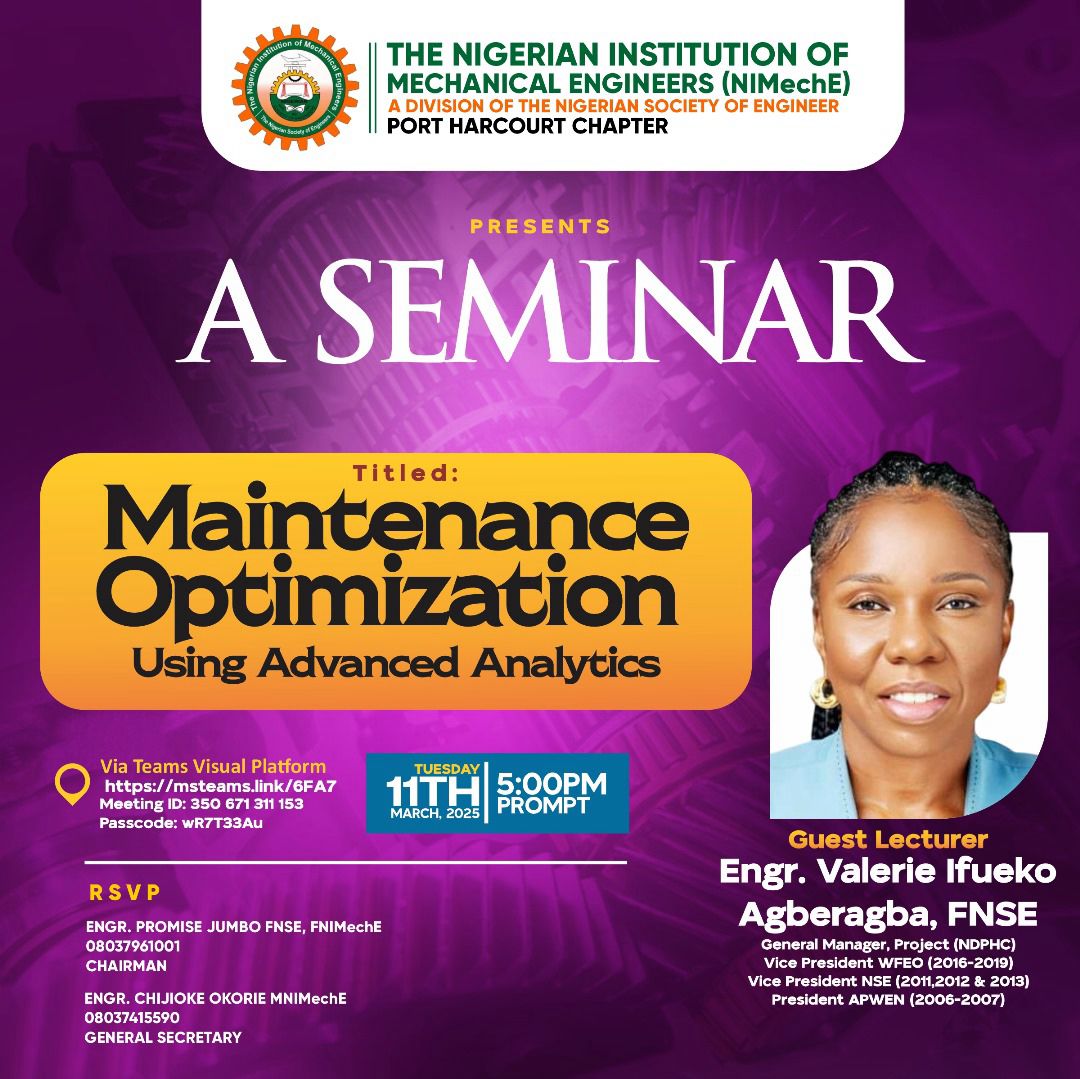

THE NIGERIAN INSTITUTION OF MECHANICAL ENGINEERS ( NimechE )

A DIVISION OF THE NIGERIAN SOCIETY OF ENGINEERS

PORT HARCOURT CHAPTER

PRESENT A SEMINAR

TITLED : MAINTENANCE OPTIMIZATION USING ADVANCED ANALYTICS.

PRESENTER : ENGR. VALERIE AGBERAGBA, FNSE

GM Generation Project NDPHC

Vice President WFEO ( 2016 - 2019)

Vice President NSE ( 2011- 2013

President APWEN ( 2006 - 2007 )

Date : Tuesday 11th March 2025, Time : 5: 00pm

THE CHALLENGE OF MAINTENANCE OPTIMIZATION

- Ensure asset reliability

- Reduce downtime

- Improve efficiency

- Traditional Method limited

UNLOCK THE POWER OF ADVANCED ANALYTICS

- Predictive Maintenance ( preventive maintenance )

- Condition - base maintenance ( monitor asset performance )

- Reliability - Centered maintenance ( Optimize reliability )

- Asset performance management ( Track and improve performance).

TYPE OF ADVANCED ANALYTICS

- Machine Learning ( patterns and predictions )

- Deep Learning ( Complex data patterns )

- Natural language Processing ( Analyze textual data )

- Statistical Modeling ( Data relationships )

BENEFITS OF ADVANCED ANALYTICS

- Improve asset reliability

- Reduced downtime

- Enhanced predictive capabilities

- Data - driven decisions

PREDICTIVE MAINTENANCE : A CASE STUDY,

Manufacturing facility implemented predictive maintenance machine learning algorithms used, downtime reduced by 25%, maintenance cost reduced by 15%.

IMPLEMENTATION ROADMAP

- Define objectives and KPIs

- Collect and integrate data

- Develop and display models

- Monitor and evaluate

CHALLENGE AND LIMITATIONS

- Data quality and availability

- Complexity of Models

- Integration with systems

- Change management and adoption.

CONCLUSION : Maintenance Optimization, Advanced Analytics offers significant opportunities. Leverage predictive models, Machine Learning, and Data - driven insights, improve asset reliability, reduced downtime, and enhance overall efficiency.